SM Roller Hemming System

1 Outline Of Roller Hemming System

The biggest advantage of roller hemming method is a facilities flexibility. Frist, It is less restriction on the flange angle. So, it can be applied up to maximum opening angle 130 ° and It is no restriction on the shape of part. In accordance with production method, it can be equipped freely. So it has a very high facilities flexibility when producing various kinds of cars. second, it is not necessary to consider the environmental impact caused by hydraulic pressure, because it does not use a driving source such as a hydraulic. And it can be a pleasant working environment because of the reduction of machine driving noise and a simple system, It is relatively inexpensive investment. It contributes to reduce Factory's space and management costs due to less overall equipment weight and space. But it is unfavorable to apply big volume of model, because it takes longer cycle time to do hemming work. Also Roller hemming is required periodical calibration. Nowadays these are to be improved by applying multiple robots or high-speed roll heads

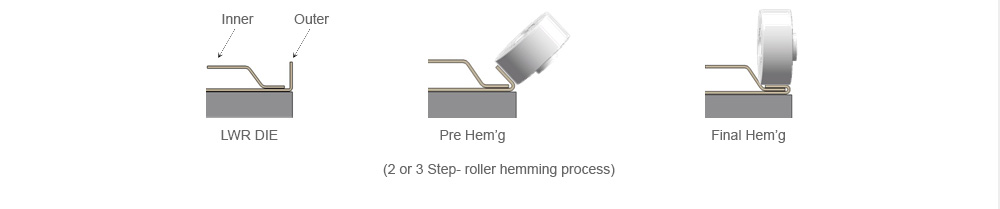

2 What is Roller Hemming?

It is used to hem the edge of flange for door, hood, trunk lid of car. The hemming flange is hemmed by robot roller tool in 2 or 3 steps instead of using hydraulic press or electric link structure.

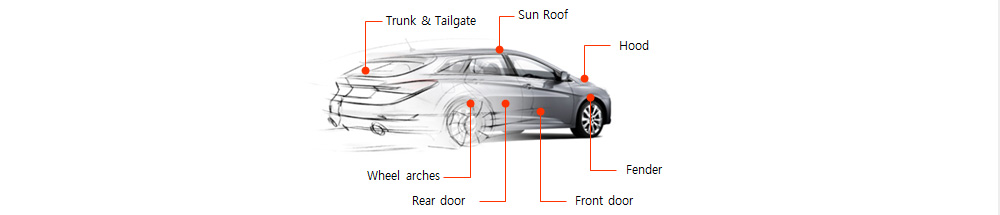

3 Applicable Hemming Part

4 SM-ROLLER HEAD

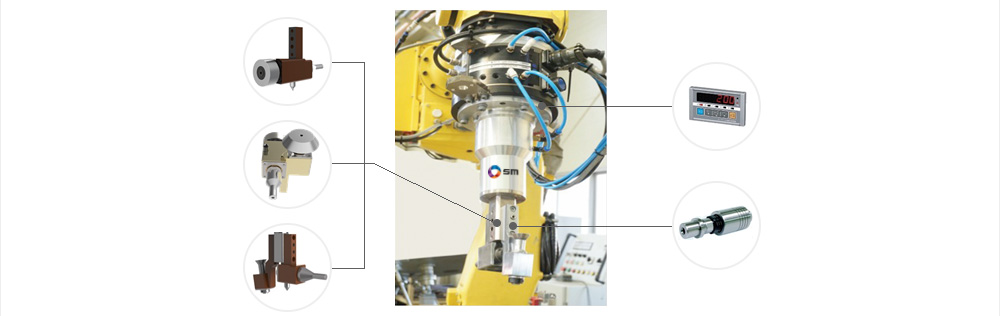

Standard Features

| Hemming Speed | 150~250 ㎜/sec |

| Hemming Force | 100 ~ 150 Kgf |

| Flange Angle | up to 130˚ |

| Roller Dia | 15~80 |

Applicable Result

| User | Project | Type |

| GMK | J series | HDTH 120 |

| GMK | V series | MOTH 100 |

| TATA | X0 series | DSTH 150 |

| IKCO | X5 series | TSTH150 |

5 SM-ROLL HEAD’s Strong Point

Roller head can be designed freely in accordance with the conditions of flange and Hemming panel. So, it can be supplied in various types of tool. It also has flexibility by standardization of assembly position. In order to maintain constant pressure, it uses pneumatic pressure. If you want to monitor hemming pressure, optionally we can adopt roller head with a built-in pressure sensor. In case of checking real time monitoring, it also can extend D/Base with PC

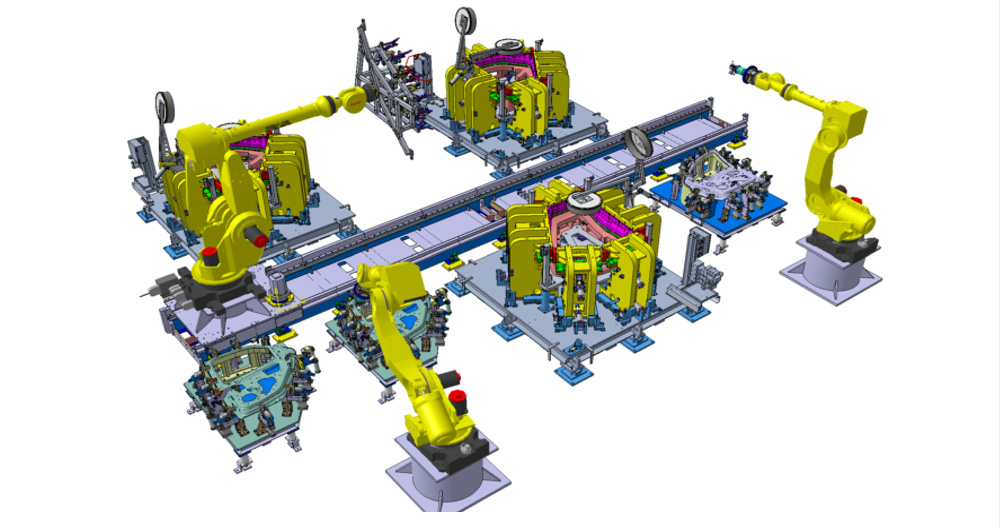

6 SM-ROLL HEM SYSTEM’s Applicable Example

7 SM-HYBRID Hemming System

It is a hybrid system combined Mechanical Hem & Roller Hem. This system can be applied big volume production of closure lines by using remarkable character of both mechanical hemming and roller hemming.