SM Servo Hemming System

1 Development Background

Hemming method for automobile body production process has mainly used the hydraulic power for power source but recently is gradually

proceeding to eliminate the hydraulic power according to the latest environmentally-friendly policies.

To respond the trend the major automobile companies including subcontractors have a tendency to focus on developing roller hemming making

use of robot and electric hemming making use of motor.

However, roller hemming using robot are indicated to have several weak points such as unsuitability to apply for mass production line due to

excessive process time, possibility to occur quality dispersion depending on robot operation skills, and necessity to conduct the regular inspection

of calibration to maintain a constant quality.

To supplement all of these problems we have developed hemming system utilizing servo motor for one of the options.

2 Specification Of SM Servo Hemming System

| SINGLE | DOUBLE | |

| Size(mm) | 730*690*740 | 944*680*676 |

| Force(kgf) | 15,000 | 25,000 |

| Cycle Time (Sec) (except form part loading / unloading) | 14 | 14 |

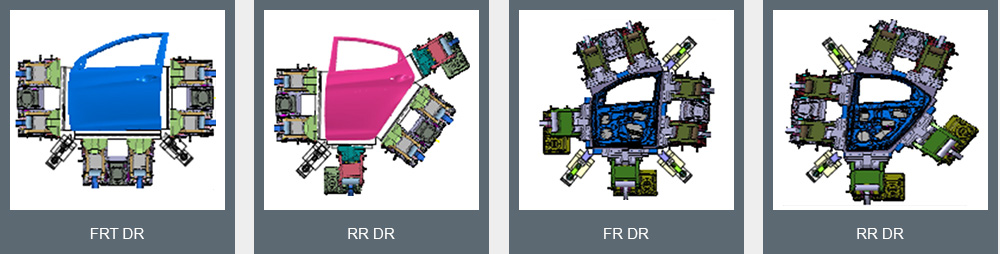

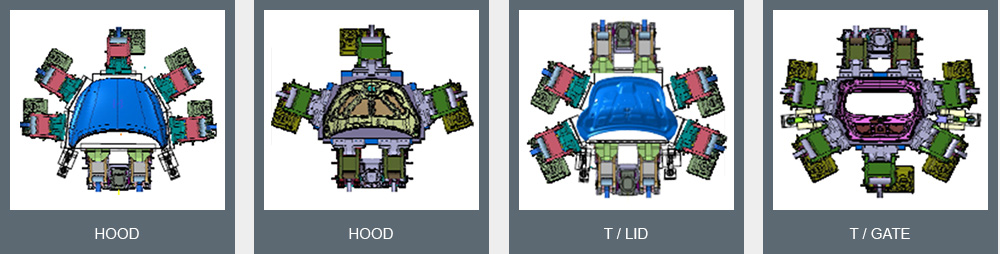

3 SM Servo Hemming Features

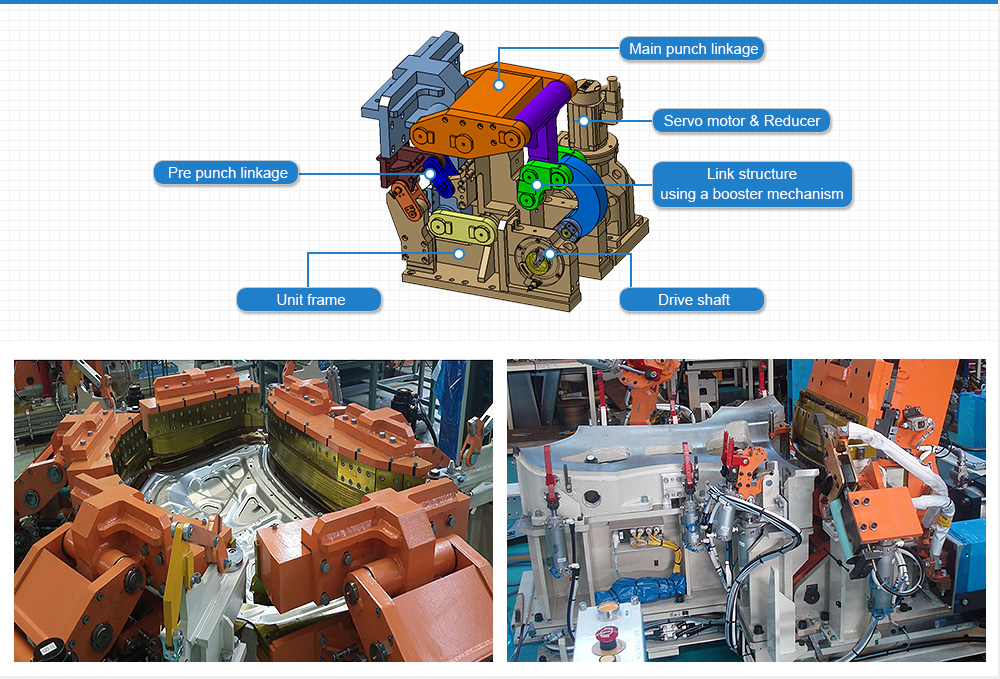

4 Layout of Hemming Punch Unit

5 Structure Of SM Servo Hemming