TMS

1 Development Background

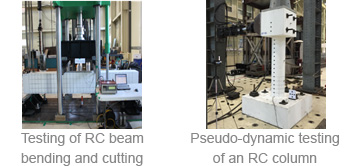

Reinforcing bar joints used in the construction of containment structure of nuclear power plant have mainly two types; sleeve joints having a filler metal of iron joints (hereinafter called "Cadweld") and cold rolled parallel screw joints (hereinafter called "parallel thread joints") for prevailing use. Cadweld needs to trim the material in foreign countries requiring specialized equipment and skilled workers which results in the poor economy and workability.

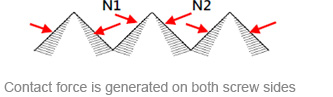

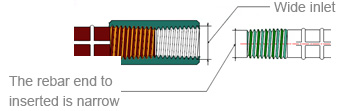

In case of parallel thread joints the workability compared to Cadweld has been improved the parallel threaded joints improved but the parallel thread joints cannot be free from the defects of initial slip due to the gap between the male thread of rebar and the female thread of screw occurring at the time of performance test since the parallel structure of the screw tightening joints are fastened tightly in one direction by the repulsive force of the tightening direction.

As this is not appropriate for seismic design and construction of containment structure of nuclear power plant given that safety is a top priority, we have

developed the harbinger tapered & threaded screw rebar joints showing the excellent clamping force and seismic performance

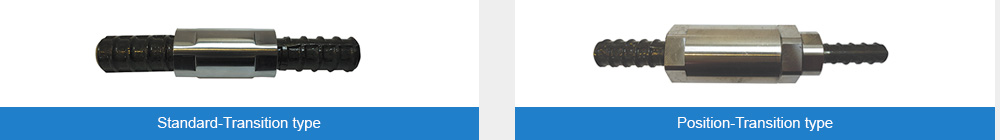

2 Types Of TMS

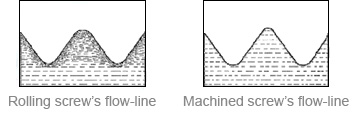

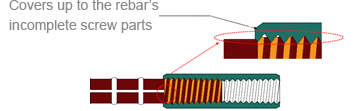

3 Features Of TMS

4 Configuration Of TMS

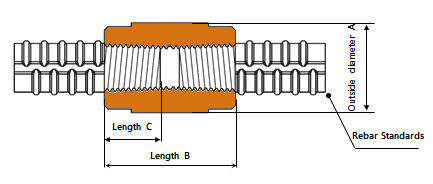

Standard Type

| Rebar Standards | Sleeve Standards | Pitch | Outside Diameter (A) | Length (B) | Rebar Clamping Length (C) |

|---|---|---|---|---|---|

| #6 | TMS 06S | 2.5 | 29 | 56 | 22.9 |

| #7 | TMS 07S | 2.5 | 33 | 64 | 26.6 |

| #8 | TMS 08S | 3.0 | 38 | 73 | 30.5 |

| #9 | TMS 09S | 3.0 | 43 | 81 | 34.4 |

| #10 | TMS 10S | 3.0 | 48 | 90 | 38.8 |

| #11 | TMS 11S | 3.5 | 55 | 100 | 43.0 |

| #14 | TMS 14S | 3.5 | 65 | 117 | 51.6 |

| #18 | TMS 18S | 4.0 | 85 | 154 | 68.8 |

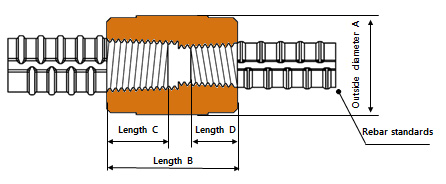

Standard-Transition Type

| Rebar Standards | Sleeve Standards | Pitch | Outside Diameter (A) | Length (B) | Rebar Clamping Length (C) | Rebar Clamping Length (D) |

|---|---|---|---|---|---|---|

| #11 + #10 | TMS 1110T | 3.5+3.0 | 55 | 105 | 43.0 | 38.8 |

| #14 + #10 | TMS 1410T | 3.5+3.0 | 65 | 115 | 51.6 | 38.8 |

| #14 + #11 | TMS 1411T | 3.5 | 65 | 120 | 51.6 | 43.0 |

| #18 + #11 | TMS 1811T | 4.0+3.5 | 85 | 140 | 68.8 | 43.0 |

| #18 + # 14 | TMS 1814T | 4.0+3.5 | 85 | 150 | 68.8 | 51.6 |

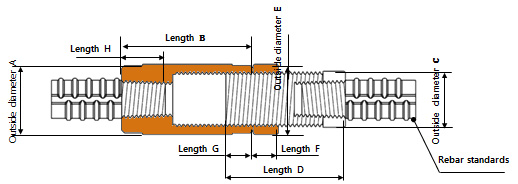

Position Type

(※ Position type: a sleeve used when a rebar cannot be rotated)

| Rebar Standards |

Sleeve Standards |

Female Screw Sleeve | Male Screw Sleeve | Lock Nut | Minumum Clamping Length (G) |

Rebar Clamping Length (H) |

|||

|---|---|---|---|---|---|---|---|---|---|

| Outside Diameter (A) |

Length (B) | Outside Diameter (C) |

Length (D) | Outside Diameter (E) |

Length (F) | ||||

| #6 | TMS 06P | 40 | 70 | 33 | 64 | 40 | 12 | 14 | 22.9 |

| #7 | TMS 07P | 46 | 81 | 37 | 77 | 46 | 15 | 17 | 26.6 |

| #8 | TMS 08P | 53 | 94 | 43 | 90 | 53 | 18 | 20 | 30.5 |

| #9 | TMS 09P | 59 | 105 | 48 | 96 | 59 | 18 | 22 | 34.4 |

| #10 | TMS 10P | 65 | 117 | 53 | 103 | 65 | 18 | 25 | 38.8 |

| #11 | TMS 11P | 75 | 130 | 59 | 114 | 75 | 20 | 28 | 43.0 |

| #14 | TMS 14P | 85 | 156 | 68 | 140 | 85 | 25 | 35 | 51.6 |

| #18 | TMS 18P | 115 | 206 | 90 | 178 | 115 | 30 | 45 | 68.8 |

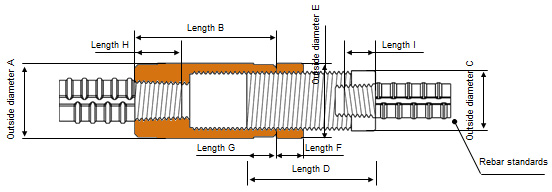

Position-Transition Type

(※ Position-transition type: a sleeve used when a rebar cannot be rotated and when splicing rebars with different standards)

| Rebar Standards |

Sleeve Standards |

Female Screw Sleeve | Male Screw Sleeve | Lock Nut | Minumum Clamping Length (G) |

Rebar Clamping Length (H) |

Rebar Clamping Length (I) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Outside Diameter (A) |

Length (B) | Outside Diameter (C) |

Length (D) | Outside Diameter (E) |

Length (F) | |||||

| #11 + #10 | TMS 1110PT | 65 | 128 | 52 | 109 | 65 | 18 | 31.2 | 43.0 | 38.8 |

| #14 + #10 | TMS 1410PT | 65 | 136 | 52 | 109 | 65 | 18 | 31.2 | 51.6 | 38.8 |

| #14 + #11 | TMS 1411PT | 75 | 144 | 60 | 120 | 75 | 20 | 34.0 | 51.6 | 43.0 |

| #18 + #11 | TMS 1811PT | 80 | 162 | 60 | 120 | 80 | 20 | 34.0 | 68.8 | 43.0 |

| #18 + #14 | TMS 1814PT | 85 | 179 | 67 | 145 | 85 | 25 | 40.4 | 68.8 | 51.6 |